Preview text:

Table of Contents

I. ABSTRACT ........................................................................................................................................... 3

II. INTRODUCTION ............................................................................................................................. 3

III. MATERIALS AND METHODS ...................................................................................................... 4

• Materials ............................................................................................................................................... 4

• Method .................................................................................................................................................. 4

IV. RESULT AND DISCUSSION .......................................................................................................... 5

• Result .................................................................................................................................................... 5

• Discussion ............................................................................................................................................. 6

V. CONCLUSION ................................................................................................................................. 7

VI. LAB NOTES...................................................................................................................................... 8 2 I. ABSTRACT

Liquid-liquid extraction is one of the separation techniques widely used in several sectors.

This procedure differs significantly from distillation as it primarily considers the relative solubility

of the species rather than their volatility. Typically, extraction is a more favorable method than

distillation for separation applications that are not cost-effective and suitable for distillation. This

experiment's purpose was to ascertain the distribution and mass transfer coefficient of Liquidliquid

extraction. This method is used to separate compounds based on their relative solubilities in two

different immiscible liquids, usually aqueous and an organic solvent. In this method after extraction

of sample with tea, solvent mixture containing methyl chloride. Liquid-liquid Extraction is

applicable for tea and by-products. The efficiency and selectivity of the extraction process are

influenced by factors like solvent choice, temperature, pH, and agitation. By optimizing these

parameters, it is possible to get higher yields and greater purity of the extracted chemicals. The

main disadvantage of the Liquid-liquid extraction method is that this method is time-consuming,

tedious, laborious and requires a large number of toxic solvents that pose a potential threat to

human health, environment, problem of emulsion formation, and if there exist lots of target

compounds with significant differences in polarity in samples, it will be difficult to obtain good

separation using a single Liquid-liquid extraction procedure.

The distribution ratio of an analyte is the proportion of its overall concentration in the

organic phase divided by the organic phase in the aqueous phase at equilibrium. The recovery of

the organic compound and enrichment factor increase as the distribution ratio of the analyte

becomes larger and that of the matrix becomes smaller, when extracting the desired organic

compound. Successful enrichment necessitates the reversal of the extraction process while

removing the matrix. Following the extraction process, selectively transferring matrix components

from the organic phase to the aqueous phase through backwashing enhances the enrichment factor. II. INTRODUCTION

Liquid-liquid extraction is a method that divides constituents by their chemical variances

rather than disparities in physical characteristics. The fundamental idea of this procedure involves

the contact between a mixture and an insoluble liquid solvent that is not capable of being mixed

with the original solution but can be mixed with the specific solute present in the original solution

but can be mixed with the specific solute present in the original solution. The transfer occurs due

to the solute’s higher solubility in the solvent present in the feed. The extract is a solution rich in

solvent and contains the desired solute. On the other hand, raffinate is the residual feed solution 3

that contains only a small amount of solute. These two phases are created when the solvent is added,

because of the disparities in densities. The experiment includes methylene chloride, benzene, and petroleum ether. III. MATERIALS AND METHODS • Materials + 1 Erlenmeyer flask 250 mL + 1 Cylinder 10 mL + Heating plate + 1 Cylinder 50 mL + Vacuum filter + Tea + 1 Beaker 100 mL + Methylene chloride

+ 1 Separatory funnel 250 mL with + Benzene stand + Petroleum ether + Balance • Method

First, get the caffeine solution from the tea by filtering off the tea with a baby towel and

funnel (get as much as possible and save the liquids). Secondly, centrifuge the mixture for five

minutes at 5,000 rpm and collect the liquid. After allowing the extract to reach room temperature,

pour it into a 250 mL separatory funnel and use 20 mL portions of methylene chloride to extract

the aqueous solution three times (to prevent the formation of an emulsion, swirl the layers rather

than shake them vigorously). Then, mix the methylene chloride extracts, and use the steam bath to

evaporate the extract until it is completely dry. Don't heat the residue any longer than is required

to cause the solvent to evaporate. Crude caffeine is left over after the solvent evaporates; some

mint smell will be evident. Move to the purification methods, to dissolve the crude caffeine,

transfer it to a clean 50 mL beaker, add 5 mL of benzene, and boil it in a hot water bath. Take the

beaker off of the heat source, pour in 10 mL of petroleum ether (with boiling range from 30 to 60

degrees Celsius), and observe the caffeine crystallize. The product should be collected using

suction filtration, cleaned with 1 mL of petroleum ether, and allowed to air dry and determine the caffeine melting point. 4 IV. RESULT AND DISCUSSION • Result

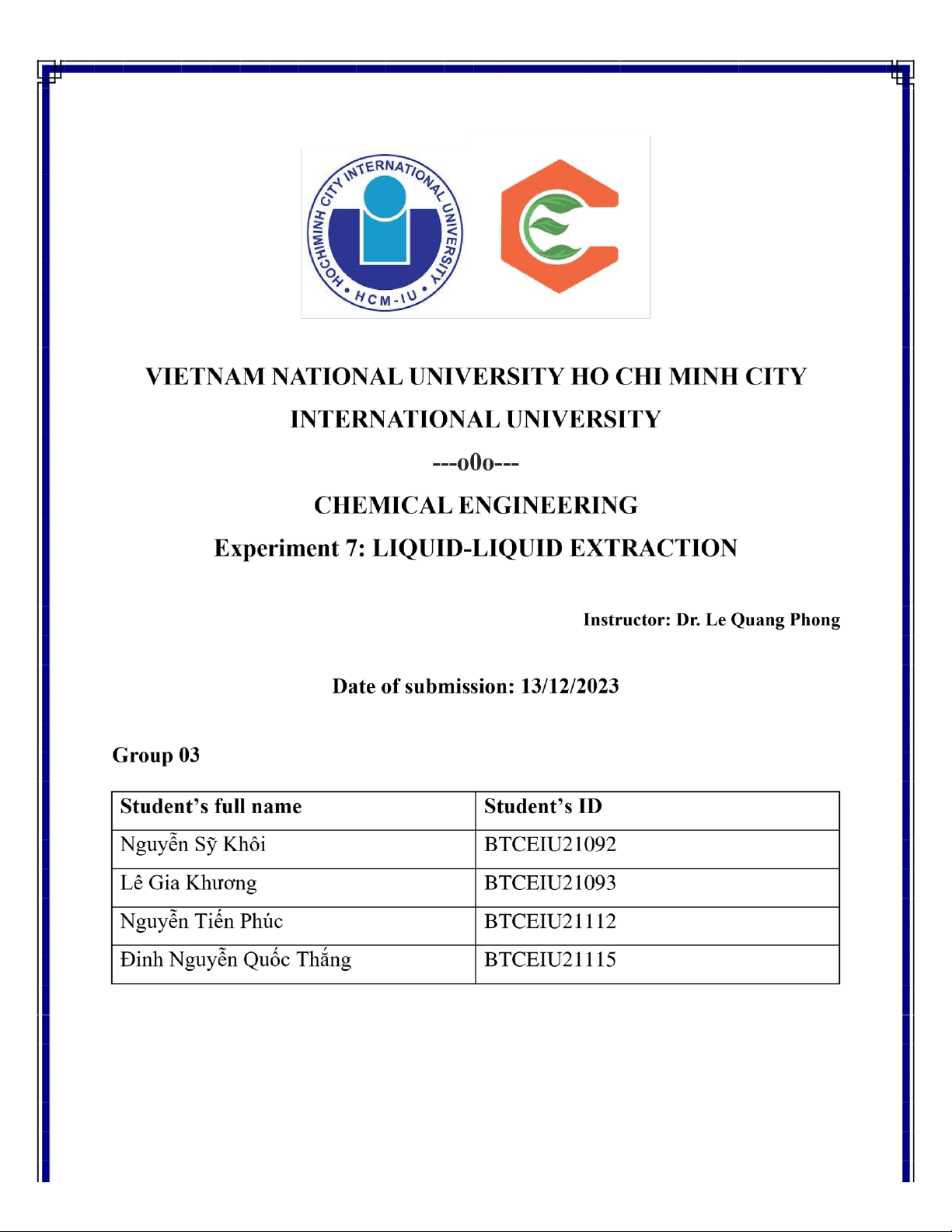

After extract caffein from tea, the sample was washed with petroleum ether as a wash

solvent because it is relatively nonpolar and can dissolve many nonpolar impurities.

Figure 1: Sample after washing with petroleum ether.

It can be observed that the caffeine recrystallized immediately after adding 10 mL

petroleum ether (30-60). Upon drying sample, the total mass of caffein upon was 0.33g.

Three percent of the mass of green tea is caffeine. Thirty grams of green tea were used in

the experiment to extract caffeine. Consequently, 0.9g of caffeine existed prior to recrystallization.

𝑊𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑐𝑎𝑓𝑓𝑒𝑖𝑛 𝑎𝑓𝑡𝑒𝑟 𝑟𝑒𝑐𝑟𝑦𝑠𝑡𝑎𝑙𝑙𝑖𝑧𝑎𝑡𝑖𝑜𝑛 0.33

%𝑅𝑒𝑐𝑜𝑣𝑒𝑟𝑒𝑑 = × 100% = × 100 % = 36.7%

𝑊𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑐𝑎𝑓𝑓𝑒𝑖𝑛 𝑏𝑒𝑓𝑜𝑟𝑒 𝑟𝑒𝑐𝑟𝑦𝑠𝑡𝑎𝑙𝑙𝑖𝑧𝑎𝑡𝑖𝑜𝑛 0.9 5

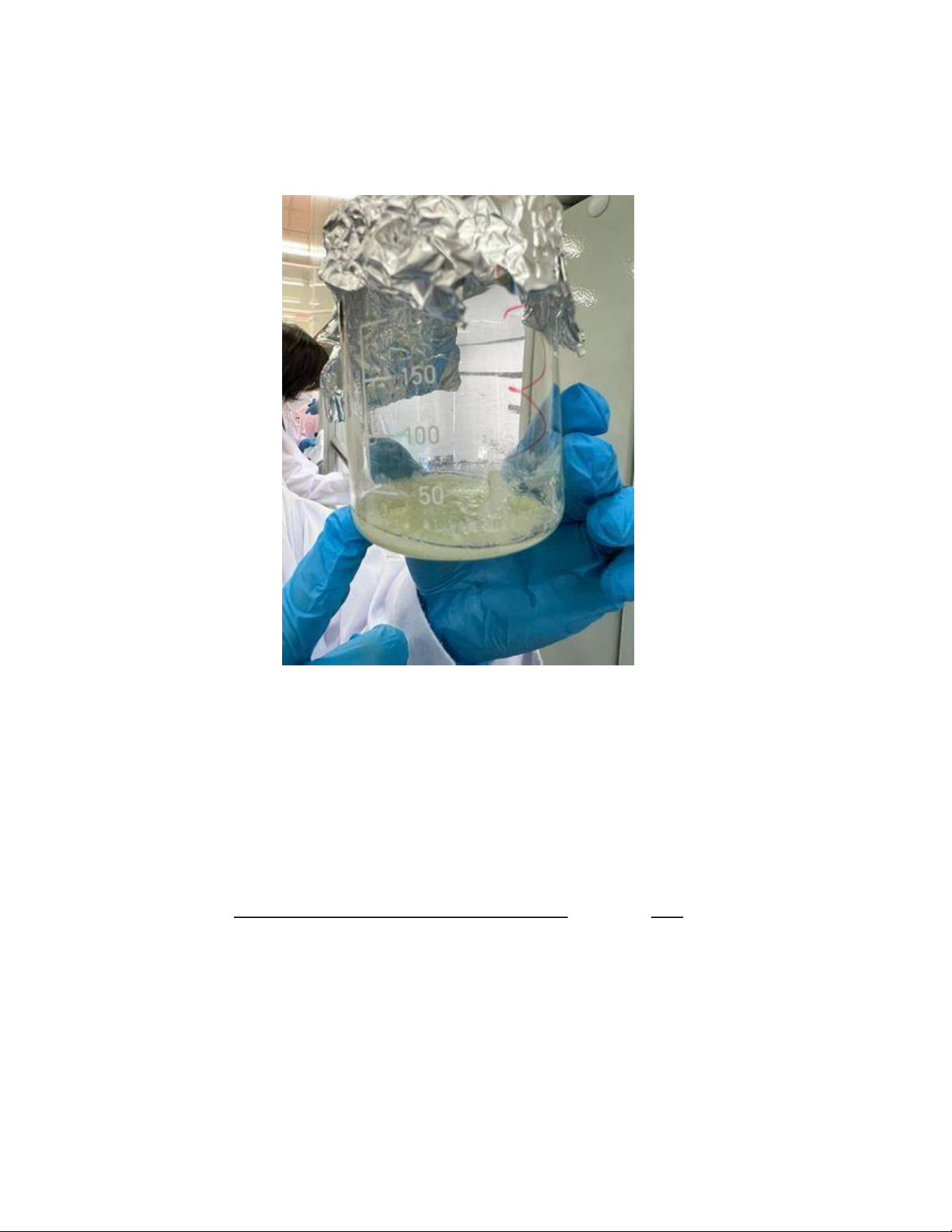

Figure 2: Melting point of sample.

In the conclusive stage of the experiment, the determined melting point of caffeine was

recorded as 234.2°C. It is pertinent to note that the accepted melting point range for caffeine is

235-237°C. The observed discrepancy between the experimental and accepted values indicates the

presence of impurities within the sample. This incongruity is suggestive of potential sources of

personal error during the experimental procedures. • Discussion

Caffeine is a polar compound; methylene chloride is either. So, methylene chloride is a

suitable solvent for the extraction of caffeine out of water. Methylene chloride is denser than water,

so it will be the bottom layer when combined with an aqueous solution in a separatory funnel.

When performing liquid-liquid extraction, it is not necessary to drain the methylene chloride and

aqueous solution out of the separatory funnel. After draining methylene chloride out of the

separatory funnel, fresh methylene chloride can be added to the aqueous solution to continue the

extraction of caffeine. Repeat the process three times to maximize the efficiency of the extraction.

Choosing a solvent to dissolve crude caffeine is particularly important in Liquid-liquid

extraction. 1g of caffeine is soluble in 46 mL of water but in 100 mL of benzene at 25oC, so benzene

is more appropriate than water. After dissolving caffeine in benzene, add petroleum ether (30-60)

to the benzene solution to recrystallize caffeine. This phenomenon is the result of its polarity.

Benzene and caffeine are polar compounds, so caffeine can be dissolved in benzene solution, while

petroleum ether is a non-polar compound, so it will reduce the solubility of caffeine in benzene

solution and allow caffeine to recrystallize.

The melting point range of pure caffeine is 235oC-238oC. Due to some technical issues

while performing Liquid-liquid extraction (I.e., shaking the separatory funnel cruelly) the melting

point of caffeine recorded was not in the melting point range (I.e., 234.2oC). This technical issue 6

formed bubbles between 2 layers of aqueous solution and methylene chloride. These bubbles took

some of aqueous solution and went down with methylene chloride. Hence, the crystal contained

some impurities from aqueous solution which leaded to the error in melting point of caffeine.

%Recovery was low (I.e., 36.7%) because methylene chloride was not enough to extract

more caffeine in the aqueous solution. The more repetition of the Liquid-liquid extraction, the more

caffeine would be extracted from the aqueous solution.

This procedure can be scaled up for industrial manufacturing because of its simplicity. The

extraction is safe because there is no reaction in the process. It can be easy to control the whole

extraction process in industry. Do not forget to release pressure drop while mixing aqueous solution

and the organic solvent to ensure the extraction system works safely and smoothly. V. CONCLUSION

To sum up, the Liquid-liquid extraction experiment demonstrated itself to be a useful and

efficient method for separating and purifying chemicals from complicated combinations. The

ability to transfer target chemicals selectively across immiscible liquid phases according to their

varied solubilities demonstrated the effectiveness of this approach. Requirements for effective

extractions included the careful selection of suitable solvents and the rigorous control of

experimental conditions, including temperature and pH.

The experiment also demonstrated how crucial it is to comprehend the chemical

characteristics of solvents and how they interact with other combination constituents. Liquid-liquid

extraction has shown to be versatile with a wide range of applications in areas including

environmental analysis, petrochemicals, and pharmaceuticals. 7 VI. LAB NOTES

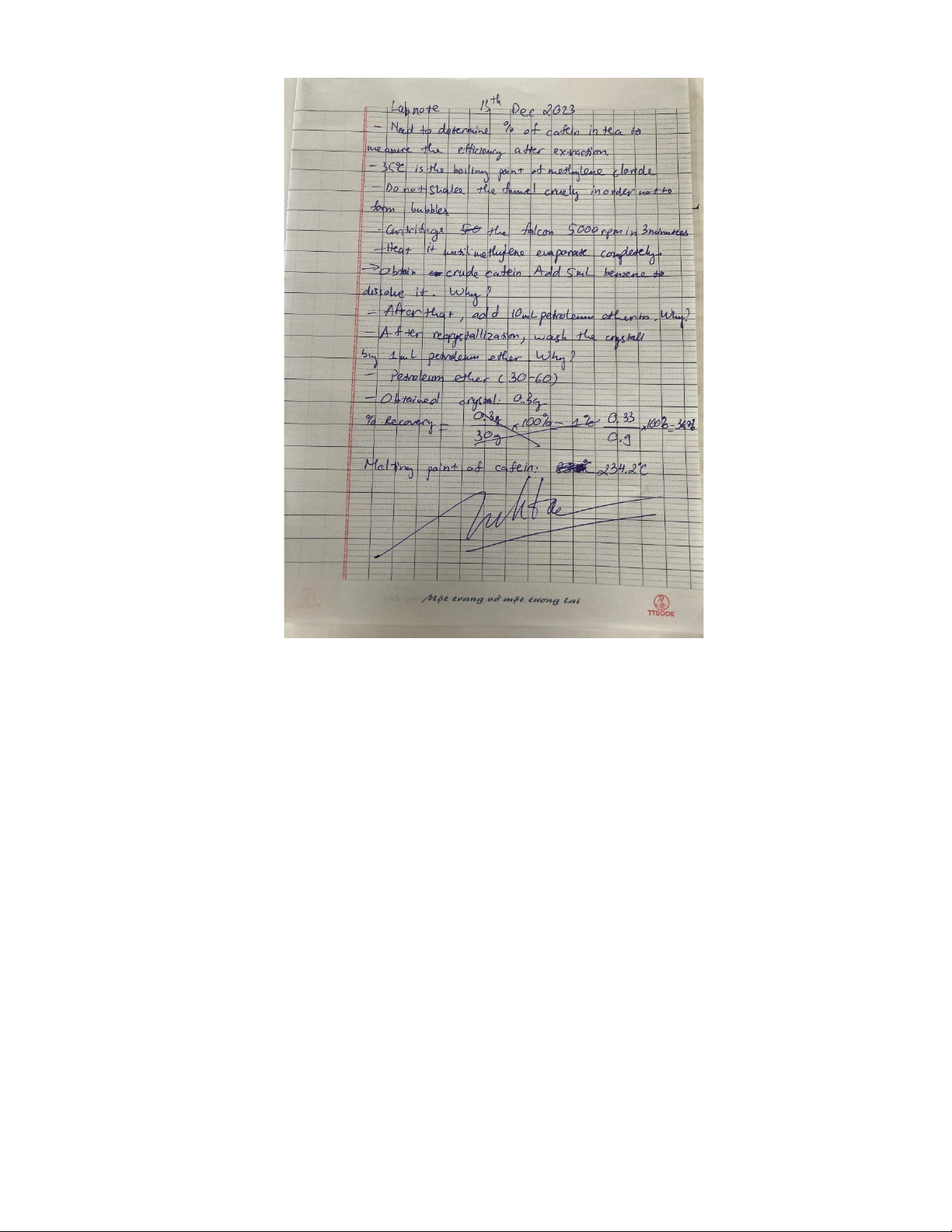

Figure 3: Lab notes 13th December. 8